| This processing machinery is for making minced meat from Alaska pollack, Cod, Hoki, Whiting and the likes. | ||||

| Alaska pollack | Cod | Hoki | ||

|

||||

|

||||

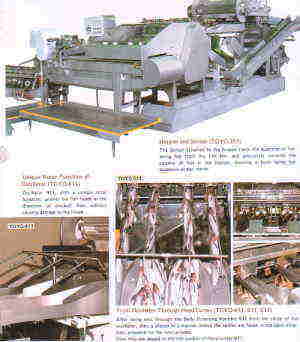

| Constant Volume Supplying Machine TOYO-311 Bally Oeienting & Feeding Machine TOYO-511 |

||||

|

|

|||

Meat Separator TOYO-405WN |

||||

|

|

|||

| 1.Application | ||||

| Alaska pollack and similar fish Total length of fish: 350mm - 600mm (adjustable) Group 1. Total length 350mm - 450mm Group 2. Total length 410mm - 600mm |

||||

| 2. Shape processed | ||||

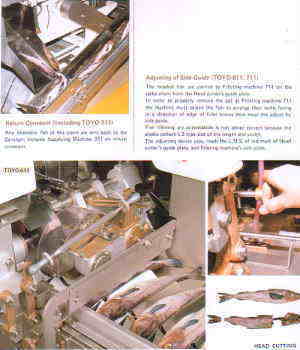

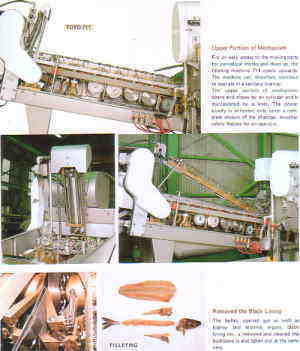

| 1. Constant Volume supplying TOYO-311 2. Head arranging TOYO-411 3. Belly orienting TOYO-511 4. Head cutting & tail cutting TOYO-611 5. Removal of guts and black lining back bone TOYO-711 6. Carrying fillet TOYO-811 7. Separation of meat and skin TOYO-405WN |

||||

| 3. Processing Capacity | ||||

| 180 - 240 fishes/minute | ||||

| 4. Electric Source & Required Power |

||||

| 1. Electric Voltage: At your commercial supplying voltage 2. Motor and required power a. 0.75kW and 1.5kW for driving conveyor of TOYO-311 b. 2.2kW for driving osciletor pan of TOYO-411 c. 2.2kW for driving spike drum and head cutter pocket of TOYO-511 d. 0.75kW for driving brush of TOYO-511 e. 1.5kW for driving rotary head cutter of TOYO-611 f. 0.75kW for driving rotary tail cutter of TOYO-611 g. 3.7kW for driving carrier belt and knives of TOYO-711 h. 7.5kW for driving screen drum and rubber belt of TOYO-405WN |

||||

| 5. Water Consumption | ||||

| Maximum at 250 liters/minuite | ||||

| 6. Materials | ||||

| Frame: Stainless steel (SUS304), SS41 iron is coated with zinc metaricon Screen Conveyor: STainless steel (SUS304) Fish Pocket: Stainless steel Geared Box: Bronze steel Pully and sprokets are made of iron and coated with zinc metaricon. |

||||

| 7. Number of Operator | ||||

| One (1) operator | ||||

| 8. Air Consumption | ||||

| 20NL/7kg/cm2 over | ||||

| TOYO Fish Filleting machine |

Send us E-mail | Contact us | Seafood machinery |

Top Page |

|

|

|

|

|